Product Description:

The orbital tube welding machine is mainly used in electronics, instrumentation, pharmaceutical, food, engineering installation, military, and other industries. It's suitable for thin-walled carbon steel, stainless steel, titanium alloy, and other materials. The welding tongs adopt a fully enclosed and full-position welding method. It utilizes an advanced full-jacketed integrated water cooling system for high-duty cycles. Coolant channels running through the entire weld head body ensure excellent heat dissipation, allowing the weld head to work continuously even at high welding currents and intensive load. This machine is digital, intelligent, stable, and reliable performance, easy to learn and operate, with functions of setting, storing, fetching, and printing.

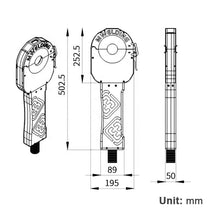

Technical parameter:

1. Welding pipe diameter : Φ38.1 mm-Φ114.3 mm;

2. Applicable wall thickness : 0.8 mm-3 mm;

3. Tungsten electrode diameter : Φ1.6 mm, Φ2.4 mm;

4. Welding tongs rotation speed : 1.5 rpm-4.5 rpm;

5. Welding mode: rotating non-winding all-position welding mode with automatic reset function, Welded pipe fittings form, straight pipe, three-way, elbow, chuck, reducer, and another docking, do not open the groove, self-fusion welding;

6. Protective gas: argon;

7. Cooling method: water circulating cooling;

8. Cooling water flow 1000 ml/min;

9. Welding tongs handle is equipped with an operation button, convenient for operation, and improves work efficiency;

10. The welding tongs are used with the MWA-200 integrated control power supply;